Lighting Optimisation

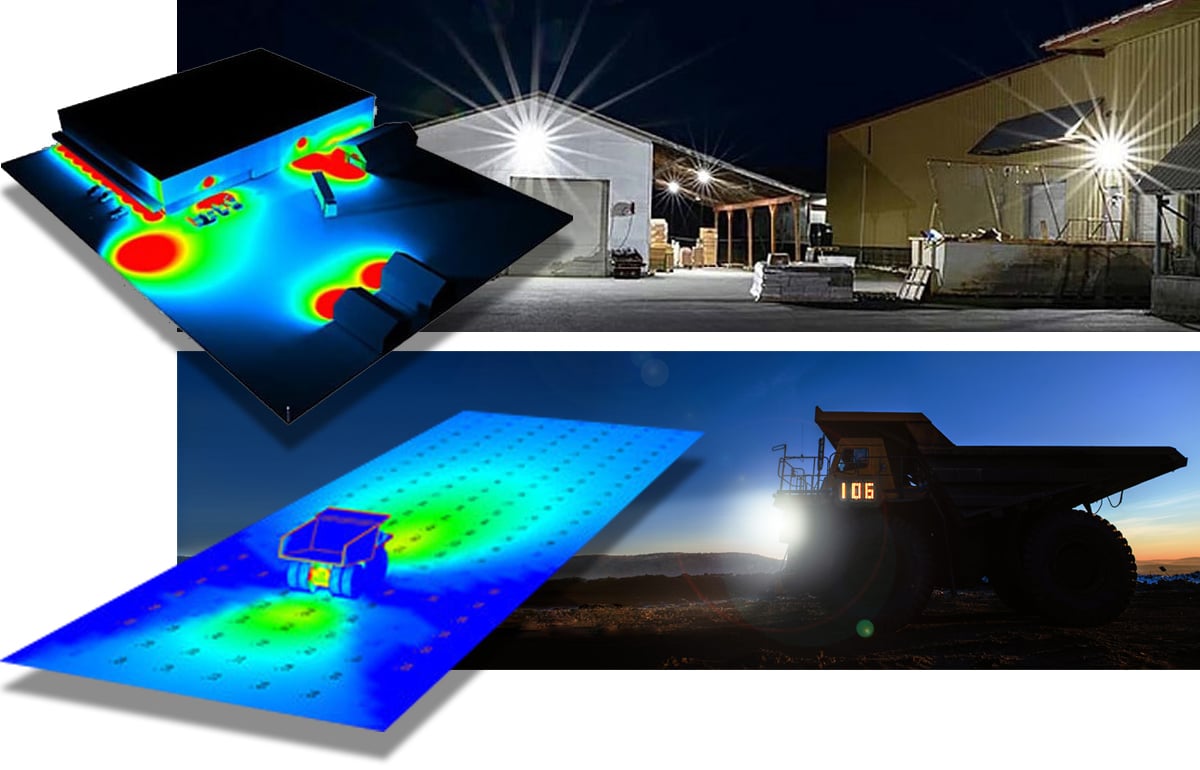

The lighting optimisation case studies in this section are developed by APS for heavy equipment and mobile fleet applications in mining, construction, marine, agriculture, forestry, utility and emergency fleets. We also develop lighting optimisation case studies for industrial applications such as light towers, workshops, warehouses, commercial buildings, ports and maritime, draglines and shovels. The case studies in this section feature isolux light maps and product recommendations.

Lighting Optimisation: Heavy Equipment / Mobile Fleets

Our goal is to narrow that gap that exists between daytime and nighttime productivity. More light isn’t usually the best solution. Selecting the right fixtures, the right setup (orientation / tilt / mounting position) and ensuring that these solutions are simple and repeatable is key. This involves so much more than just recommending a fixture. At the stores / maintenance / installation level, it involves re-thinking the labelling system and providing installation guides so that the right fixture is fitted correctly each time. Dealing with glare, reflection from different road surfaces and materials, fog, dust, rain / snow and mud are a few of the issues APS customers face each day. Understanding the type of operator: person in a cab, 2,500km from site in a remote location (using cameras / sensors) and autonomous vehicles, changes the solution. Contrast, visibility and depth perception are severely impacted in poor lighting conditions. Haul truck speeds are reduced; operator errors increase as early fatigue sets in. With improved lighting you can run your machines more efficiently, produce more tons and reduce damage and maintenance costs; and improve safety. If you are looking for productivity gains when the sun sets, let APS work with your team to develop a better solution. APS has a growing data base of equipment fit outs and lighting plans that we would like to share.

Lighting Optimisation: Industrial

Over the past 15 years APS has been working with mine sites, ports and industrial projects on their AC lighting requirements. It has only been over the past 5 years that LED Lighting technology has reached the level of lighting output needed to truly replace HPS, MV and Metal Halide lighting sources. Please contact your APS team to talk through these applications and your projects standards and unique challenges. The development of lighting plans and layouts can be undertaken at a relatively low cost, providing your team with the surety that the solution will meet or exceed your lighting standards.

Lighting Optimisation: Heavy Equipment / Mobile Fleets

Our goal is to narrow that gap that exists between daytime and nighttime productivity. More light isn’t usually the best solution. Selecting the right fixtures, the right setup (orientation / tilt / mounting position) and ensuring that these solutions are simple and repeatable is key. This involves so much more than just recommending a fixture. At the stores / maintenance / installation level, it involves re-thinking the labelling system and providing installation guides so that the right fixture is fitted correctly each time. Dealing with glare, reflection from different road surfaces and materials, fog, dust, rain / snow and mud are a few of the issues APS customers face each day. Understanding the type of operator: person in a cab, 2,500km from site in a remote location (using cameras / sensors) and autonomous vehicles, changes the solution. Contrast, visibility and depth perception are severely impacted in poor lighting conditions. Haul truck speeds are reduced; operator errors increase as early fatigue sets in. With improved lighting you can run your machines more efficiently, produce more tons and reduce damage and maintenance costs; and improve safety. If you are looking for productivity gains when the sun sets, let APS work with your team to develop a better solution. APS has a growing data base of equipment fit outs and lighting plans that we would like to share.

Lighting Optimisation: Industrial

Over the past 15 years APS has been working with mine sites, ports and industrial projects on their AC lighting requirements. It has only been over the past 5 years that LED Lighting technology has reached the level of lighting output needed to truly replace HPS, MV and Metal Halide lighting sources. Please contact your APS team to talk through these applications and your projects standards and unique challenges. The development of lighting plans and layouts can be undertaken at a relatively low cost, providing your team with the surety that the solution will meet or exceed your lighting standards.

Lighting Optimisation Case Studies

Case Study: LY400 Walkway / Conveyor Fixture

Case Study: Komatsu PC2000-8 Lighting Design

Case Study: Truck Dump Apron Feeder

Case Study: Wharf Approach Lighting

Case Study: Workshop / Gear Shed – Exterior Lighting Solution

Case Study: Lighting Design for Power Plant Cooler Rooms

Case Study: Bucyrus-Erie 1570 Dragline Lighting Solution

Case Study: Light Replacement for Tower Light Trailers

Optimised Lighting Solutions: Industrial